Viton has years of proven success in the field and provides outstanding durability. While both viton and buna seals both serve as great sealing options at moderate temperatures viton is far superior to buna for high temperature applications.

O Ring Material Selection Guide O Ring Material Comparison

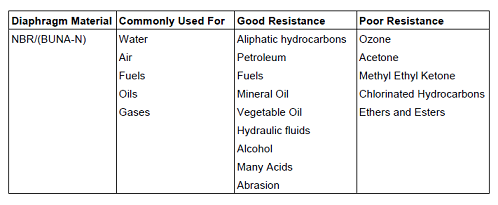

Difference between buna n and viton. Viton is the choice over buna for high temperature applications. When comparing buna rubber also known as nitrile buna n perbunan or nbr and fluorocarbon also known as viton both provide excellent compression set resistance and both are designed to resist most oils and lubricants especially petroleum based lubricants. Buna n is another option when outstanding resistance to oil hydrocarbon and chemicals is required. As a sealing option the crucial difference between buna and viton is the temperature range the materials function in. Also called nbr or buna n nitrile o rings are probably the most economical and widely used elastomer out there. Meanwhile buna is only effective in the same manner up to 250f and is the better option for low temperature seals as low as 30f.

For example viton over buna is essential for high temperature applications which provides an indefinite seal up to 400f and about a 2 day seal for temperatures up to 600f. Buna on the other hand is only effective up to 250f. The key difference between buna n and viton is that buna n is a copolymer of butadiene and acrylonitrile whereas viton is a copolymer that contains a high amount of fluorine containing units. Ketones low molecular weight esters and nitro containing compounds. The key difference between buna n and viton is that buna n is a copolymer of butadiene and acrylonitrile whereas viton is a copolymer that contains a high amount of fluorine containing units. Viton and buna seals have several very crucial differences that make them especially well suited to certain applications.

Here well look at viton vs nitrile o rings to see where each should be used and why. Excellent oil and air resistance both at low and high temperatures. Hexaflouropropylene vinylidene fluoride 10 f 400 f. Very good chemical resistance. All aliphatic aromatic and halogenated hydrocarbons acids animal and vegetable oils. Viton is better at 200 f but not necessarily at 140 f.

Viton seals provide an indefinite seal for temperatures up to 400f and for temperatures up to 600f they offer an excellent seal for more than 48 hours. Viton seals hold indefinitely at temperatures up to 400f and can last up to 48 hours at temperatures up to 600f. Due to the difference in the chemical structure of these two materials they exhibit a different set of properties which will be discussed in this article. Viton 4 fluoro elastomer. Buna n tank gaskets are comprised of a synthetic rubber copolymer and are very well suited to storage of crude oil and other petrochemicals.