Yeah you can tig weld it but it need to be professionally done it is a very difficult job as the alignment is very important. This meant either pulling the head to extract or deal with the 4 inches of available space to.

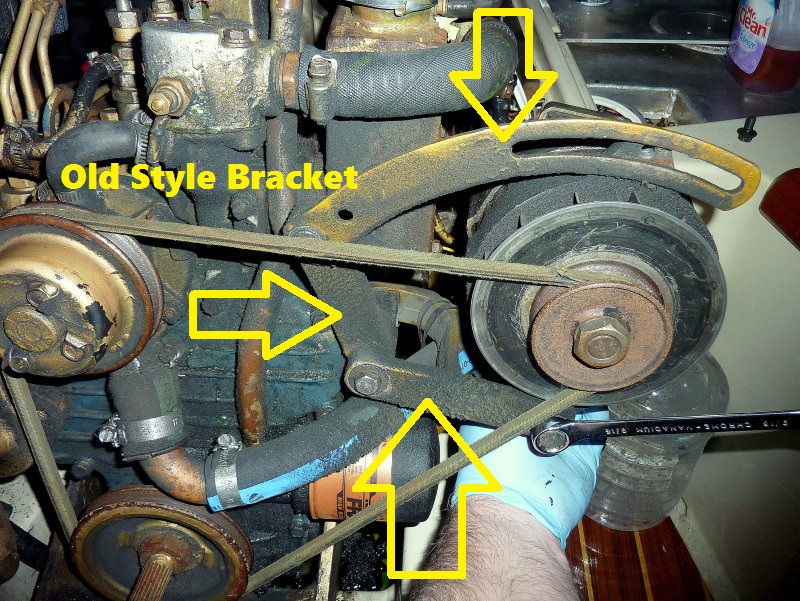

240 Alternator Bracket Broken Bolt Volvo Forums Volvo

Alternator bracket bolt broken. Apparently it must have been the alternator bracket and case shaking around before. Check that the pivot holes arent all wallowed out in your alternator they sometimes need to be bushed. But you have to know why did it break in the first place. The bolt had quite a bit of material in the threads. I was able to get the alternator back in place. Two of the alternator bracket bolts broke off in the head of my 1992 e350 ambulance.

I just tested my alternator a few weeks ago and it was good so id rather not buy a new one. Can you get at the broken off bolt with a dremel. Belt tensioner bolt broke flush with bracket how can i remove this bolt you can use a centre punch to start loosening the broken boltjust keep tapping it in the undo directiona bit of patience and perserverance is required here. I read this in an internal honda tech bulletin. How to remove a broken off bolt. Alternator bolt broken vw mkiv a4 tdis ve and pd if the thing holding it in is a broken bolt id try to hold the broken bolt and get the nut off of it then try to push it out in an area where theres clearance.

This bracket should not be subjected to large forces. I think you may have excessive tension or may be misalignment in the belt. The compressible bushings on the forward brackets do a good job of holding things in place and there was enough thread left to get the bottom bracket bolt to bite. The ear is definitely broken off the engine not the alternator. Its best for bolts 14 or larger and the shorter the better but it sure will surprise you. If so you could use a cut off blade to cut a groove in the end of the bolt and then unscrew it with a flat blade screwdriver.

Allmost looked like jb weld. This method works great. The rear right mounting ear on the alternator case threaded for the long bolt is cracked also. The problem with the constant alternator bracket stay breaking is most likely from an improperly torqued lower alternator bolt.