Aeroquip is the professionals choice and is the only company that designs engineers manufacturers and tests its hoses and fittings. Torque specification guidelines nut minimum maximum size 1torque torque1 02 50 80 03 70 105 04 100 140 05 130 180 06 150 195 08 270 350 10 360 430 12 460 550 16 700 840 20 850 1020 24 900 1080 32 1800 2000 1torque values are shown in inch pounds for aluminum fittings.

How To Torque Unistrut Fittings Unistrut Service Co

An fitting torque specs. When using aluminum and steel fittings use the torque for the aluminum fitting. Liquid pipe sealant containing no teflon is the only pipe sealant recommended. This value must be added to the torque value. Brass and steel pipe thread npt installation procedure and torque specification table and chart. Good seal but prevents damage to the fitting by over torque. Flats from wrench resistance ffwr or flats method.

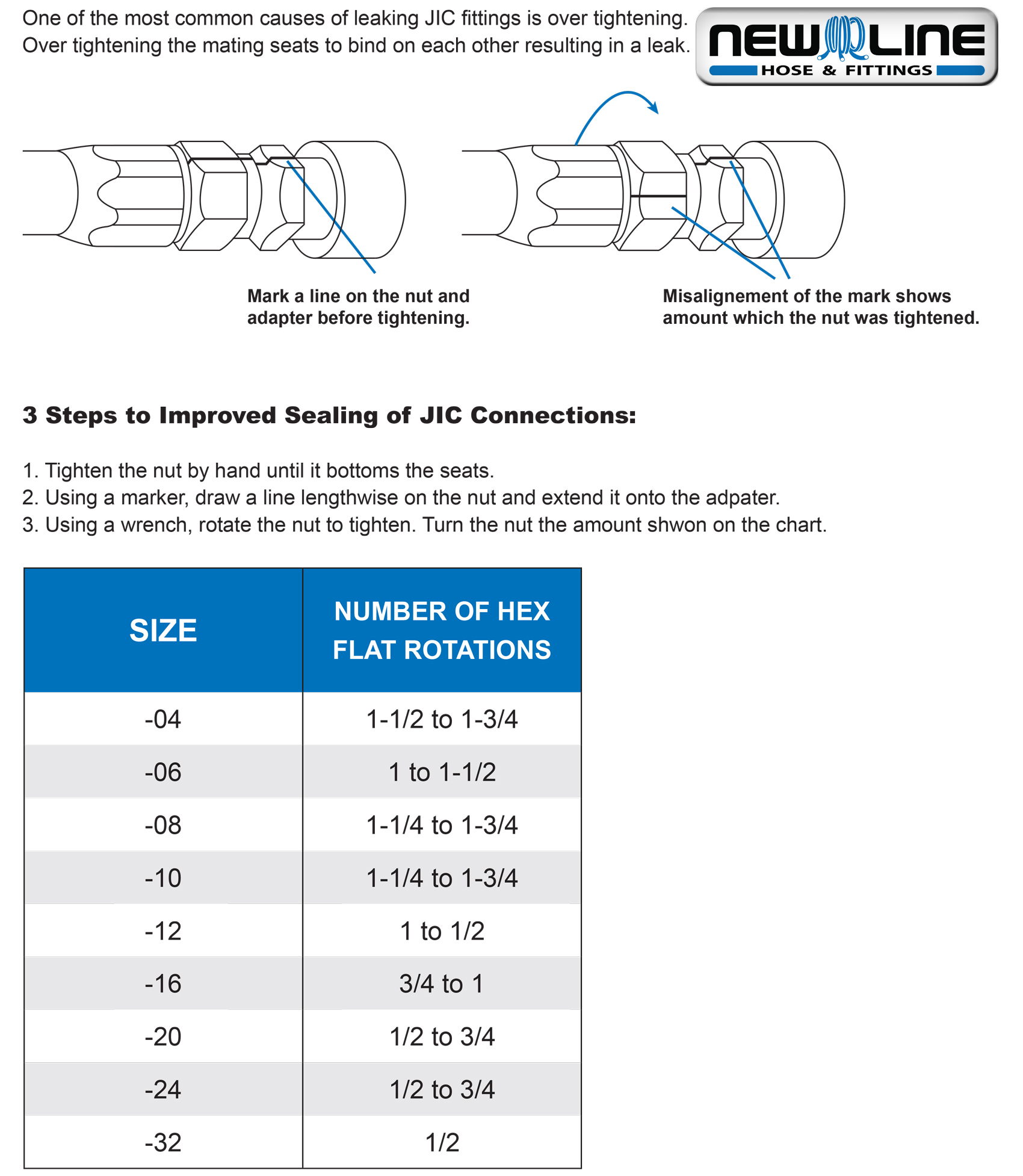

Can you see the confusion starting. Tighten to recommended torque for the corresponding thread size from the table below. Jic torque specifications. Here is a list of torque values for each an fitting size. Torque values for installing steel or malleable iron pipe plugs or fittings with pre applied loctite 516 banding are given belowall threaded connections should be lubricated before assembly. Quality technology over the years our customers have experienced superior quality industry support depth of product line and customer service from aeroquip performance products.

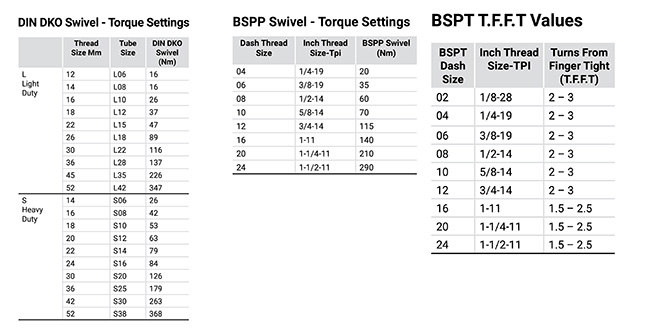

Fluids piping and hydraulic design data. Tfft assembly turns from finger tight with pipe thread sealant or teflon tape applied. The idea behind an hoses and an fittings was to provide a flexible alternative to rigid tubing in plumbing systems on aircraft and military vehicles. Do not force an improperly bent tube into alignment figure 4 or draw in too short a tube using the nut. Torque specs for an fittings. An hose sizes were designed to match the id sizes of these rigid tubes.

12 inch pounds 1 foot pound these torque values apply to an connections only not flared tube or compression fittings. Never use teflon tape. The torque required on an5 516 nuts varied between 18 22 inlbs. Dont be misled by other brands that claim performance but buy their. Align the tube on the flare nose of the fitting body and tighten the nut using one of the two methods below. If valve is connected to female swivel connection refer to swivel manufacturers torque recommendation for that joint.

Sizes for rigid tubes were already standardized with sizes called out by tubing od 316 12 etc. The table below lists the torque range for each an fitting size. Standard maintenance practice dictates that mechanics add this value to the specified torque. Pipe thread installation torque table chart. A random sample of new and used an365 4 and 5 nuts shows that the torque required to turn an4 14 nuts varied between 15 19 inlbs. Torque recommendations below are for valve connected to a compatible fitting adapter or block.