Funded wholly through the vccs office of professional development. If air is escaping through the pcv outlet the piston rings are faulty.

How To Do A Leak Down Test

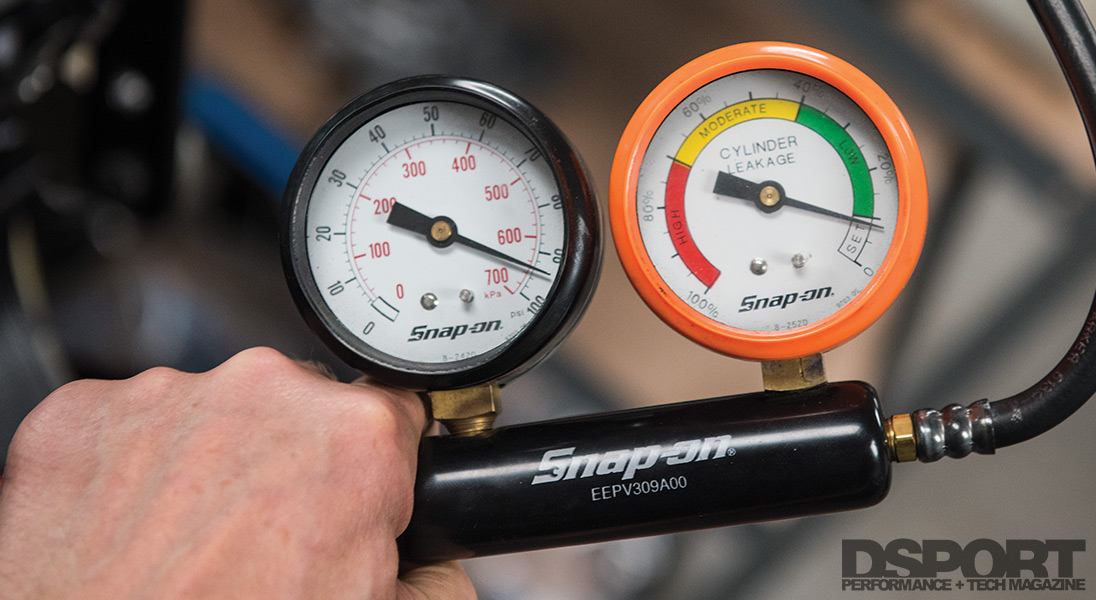

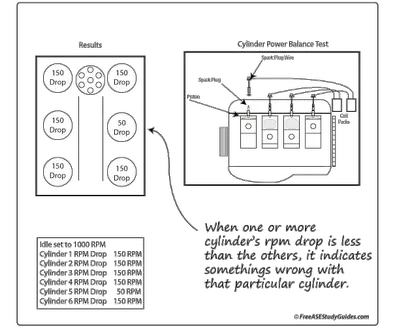

Cylinder leakage test results. How to perform a cylinder leak down test and interpreting results. So a compression test measures how well your engines cylinders are sealing. Rings rotate around the p. Always refer to the manufacturers specifications before performing any automotive test. It shows the percentage of leakage and pinpoints the part causing the compression leak. Performed a cylinder leakage or leak down test after a cylinder balance and a cylinder pressure test has verified a problem with the cylinder.

Consequently good cylinder leakdown readings should be below 5 8. Results everyone wants to have a hero engine but dont believe all the hype you hear about 2 percent leakage engines. Any reading that is more than zero indicates some leakage. I might break out my leak down tester after i find a cylinder with low compression or i might start with a leak down tester when i suspect a mechanical problem with the engine. The rings if you feel like it but its a waste of time on anything but a 2 stroke engine where the end of a ring can get hung up in a transfer port and those pistons have pins in the ring grooves to prevent that from happening. The procedure is similar to a compression test to a point.

Always make sure to test cylinder leakage with the piston at the top of. Cylinder leak test readings a zero reading means that there is no leakage in the cylinder at all. If air bubbles appear from the radiator neck the head gasket most likely the cylinder head or the blocks deck are at fault. Doing a cylinder leak down test can tell you more about your engine than you think. Also a cylinder leak down test can pinpoint issues in specific areas that other tests can not. The tester then measures the volume of air needed to maintain a predetermined pressure in the cylinder.

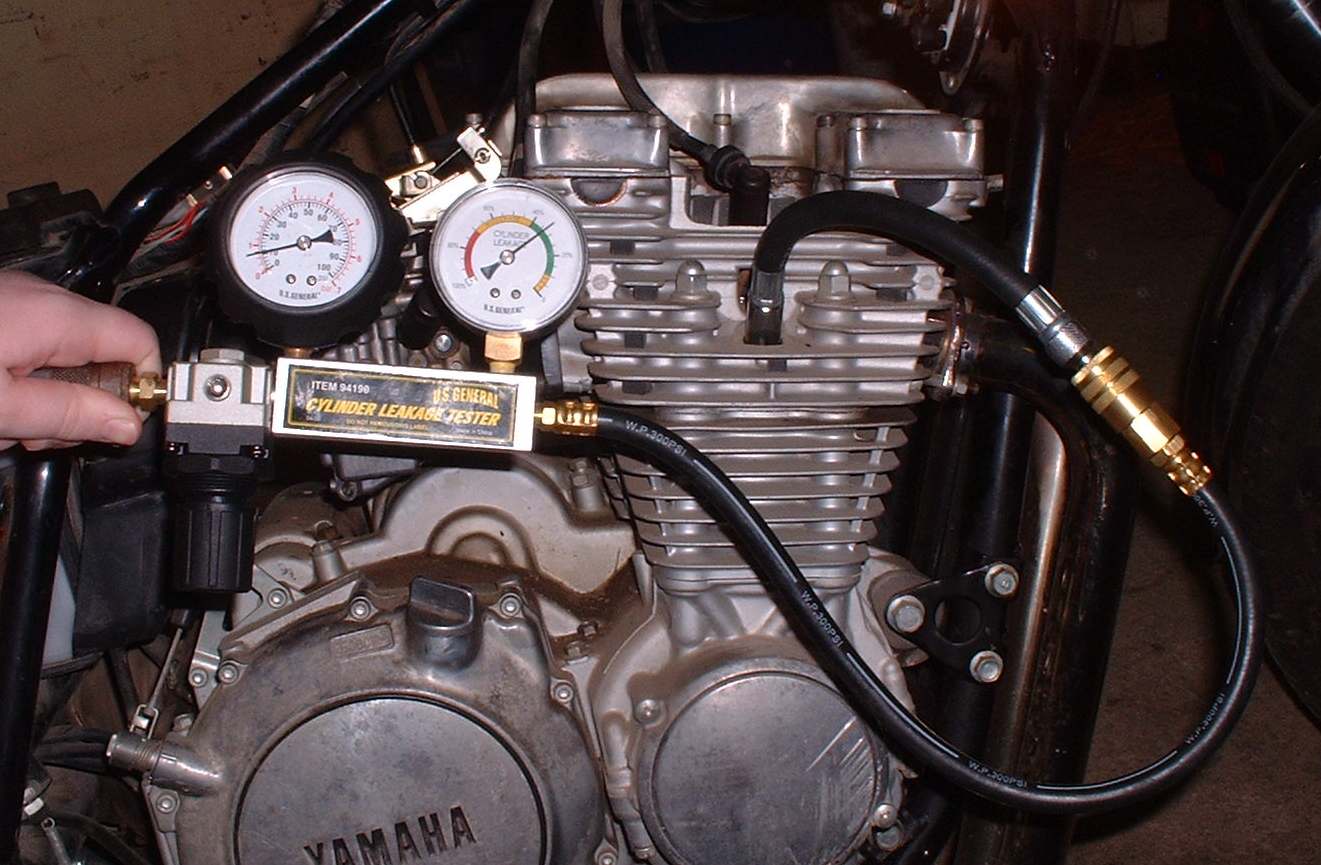

Remove the spark plug and place the problem cylinder at tdc top dead center of the compression stroke. A reading of 100 percent indicates that the cylinder will not hold any pressure whatsoever. Then using a similar type of connector as the compression test we fill the cylinder with pressure. This is done by inserting compressed air around 100 psi into the cylinder at tdc and then measuring how much is lost from the seals. The leakdown test measures how well the cylinder is sealing. A cylinder leak down or cylinder leakage test is actually similar to a compression test.

To perform the test you must first remove the spark plug on the cylinder youre going to test. The cylinder leak down test reading is expressed in a percentage.

.ashx?modified=20180416133305)