Building your first harness. Use 3m super 33 tape to keep your work together.

Wiring Harnesses Britech

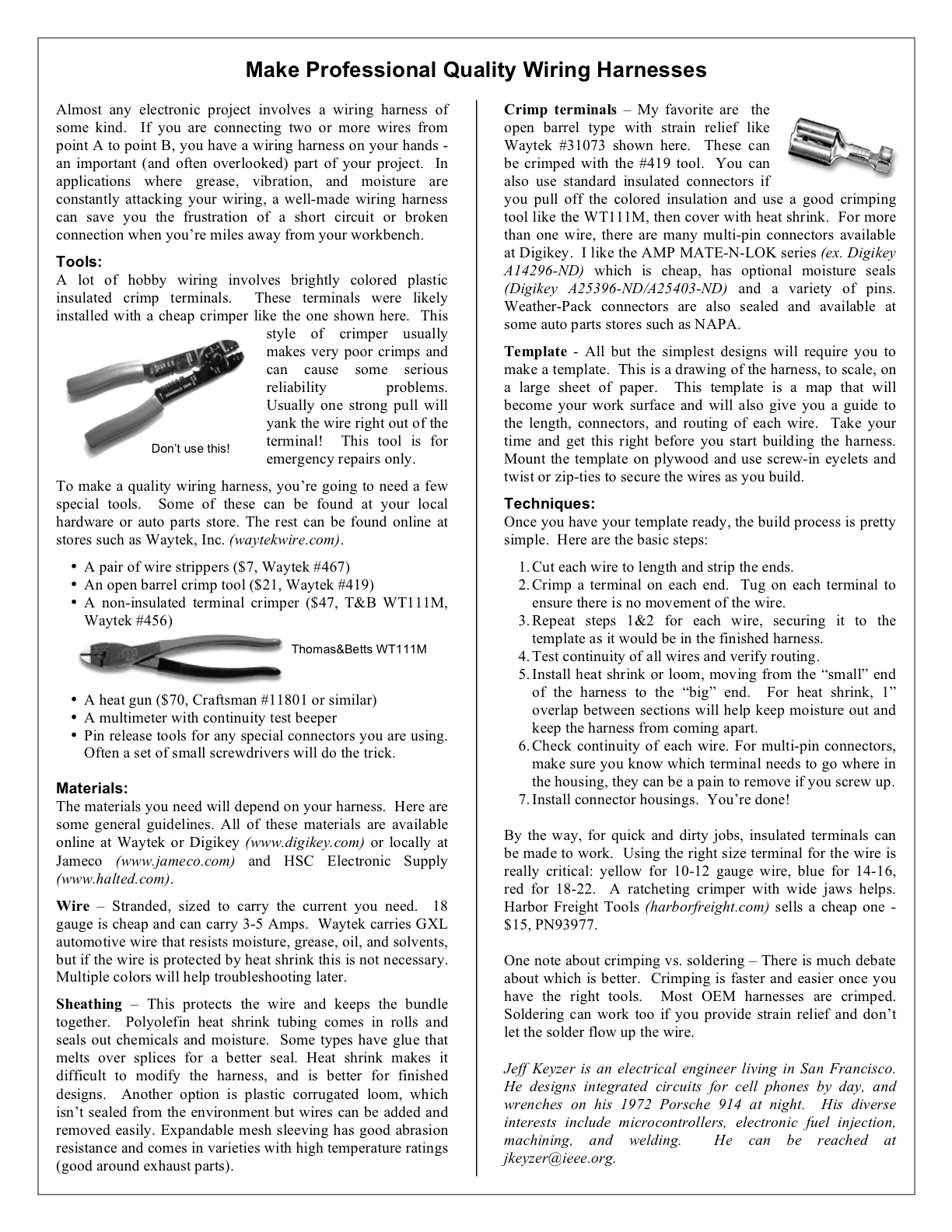

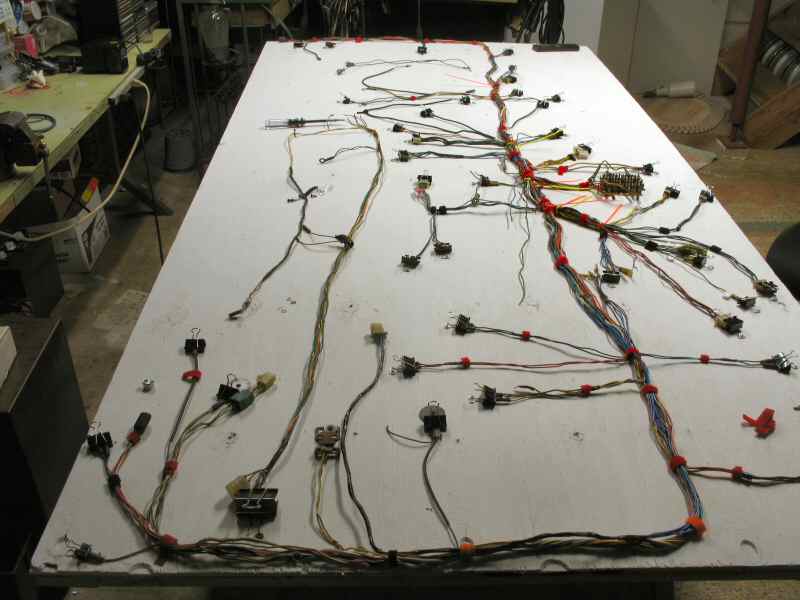

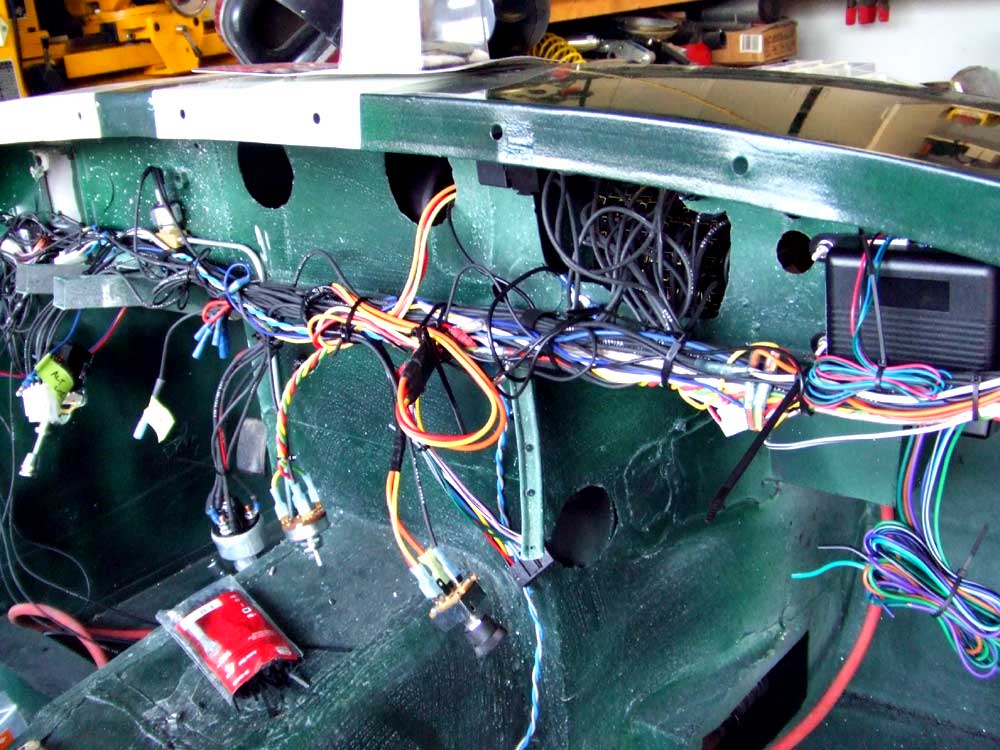

How to build a wiring harness. Use enough force such that the two parts will be crimped but not so much that the wire gets damaged. Build your harness on the bench not in the vehicle. How to make a diy simple wiring harness for any ls swap possible. After putting down the design you cut the wires into desired lengths using a wire cutting machinecutter. Insert the terminal into the wire then use the pliers to squeeze the wire and terminal together. That meant i had two options for putting it back on.

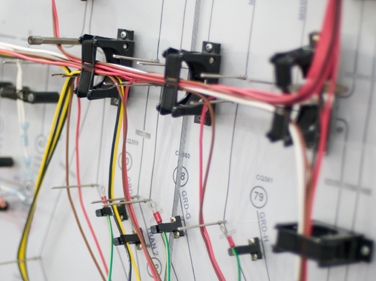

To make a custom trailer wiring harness you first have to come up with an intended design based on the. I hope you enjoy and please subscribe. Its very easy you only need a few sensors that the pcm needs to see to caculate afrs. Now im attempting to build a wiring harness from scratch and its a learning experience. How to custom trailer wiring harness. Plan your work as you just learned.

The 1972 honda sl125 i brought home from the barber vintage festival looked like a super cool commuter. Before i show you how to build a harness from scratch lets talk about some fundamental harness building basics. Group wiring together that will run in a common direction. Only problem is the bike had all of its lights and street legal bits yanked off at some point. Once the above step has been completed pull the heat shrink over the crimped wire edge and terminal seam. Ensure that the tubing closes tightly over the two parts.