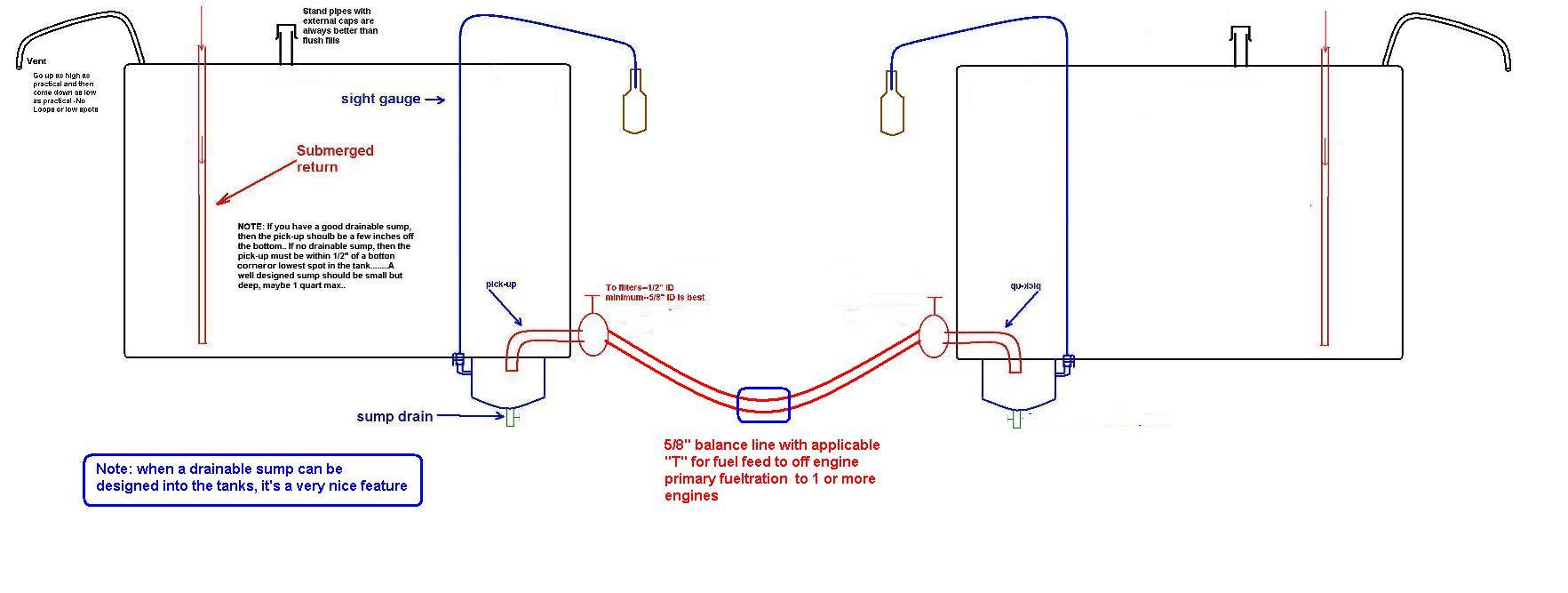

It has four ports. The hose should run as straight as possible at this point in a manner that allows any fuel to drain back into the tank via gravity.

Boat Fuel Systems Boatus Magazine

How to properly vent a fuel tank. And required vent capacity 366920 cfh. This is important when a tank is in a critical situation such as in the event of a fire. Find tank size on table a which can be found on page 5. Do note that tank above is a standard liquid transport rail car and weighs approximately 68000lbs 34 tons. A typical vent line will run sideways across the top of the tank until it reaches the hull side and then angle upward to the vent fitting. Proceed to step 5.

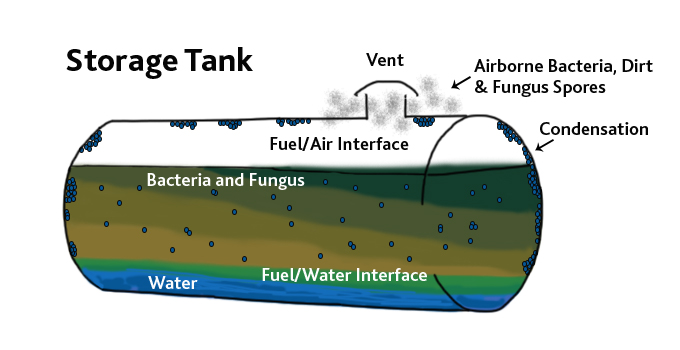

Step 2 wetted area table if tank size is not listed on table a page 5 wetted area. Regular maintenance of a charcoal canister ensures that a gas tank is vented properly. Open the vent after you connect the fuel hose and tank to your motor. The orb 8 outlet an an 8 return line port. It is imperative any tank storing class 31a flammable liquid needs to have an emergency vent under australian and new zealand regulations. The filter traps the fumes and sends them back to the engine through a vacuum hose to be thoroughly burned before being released into the air.

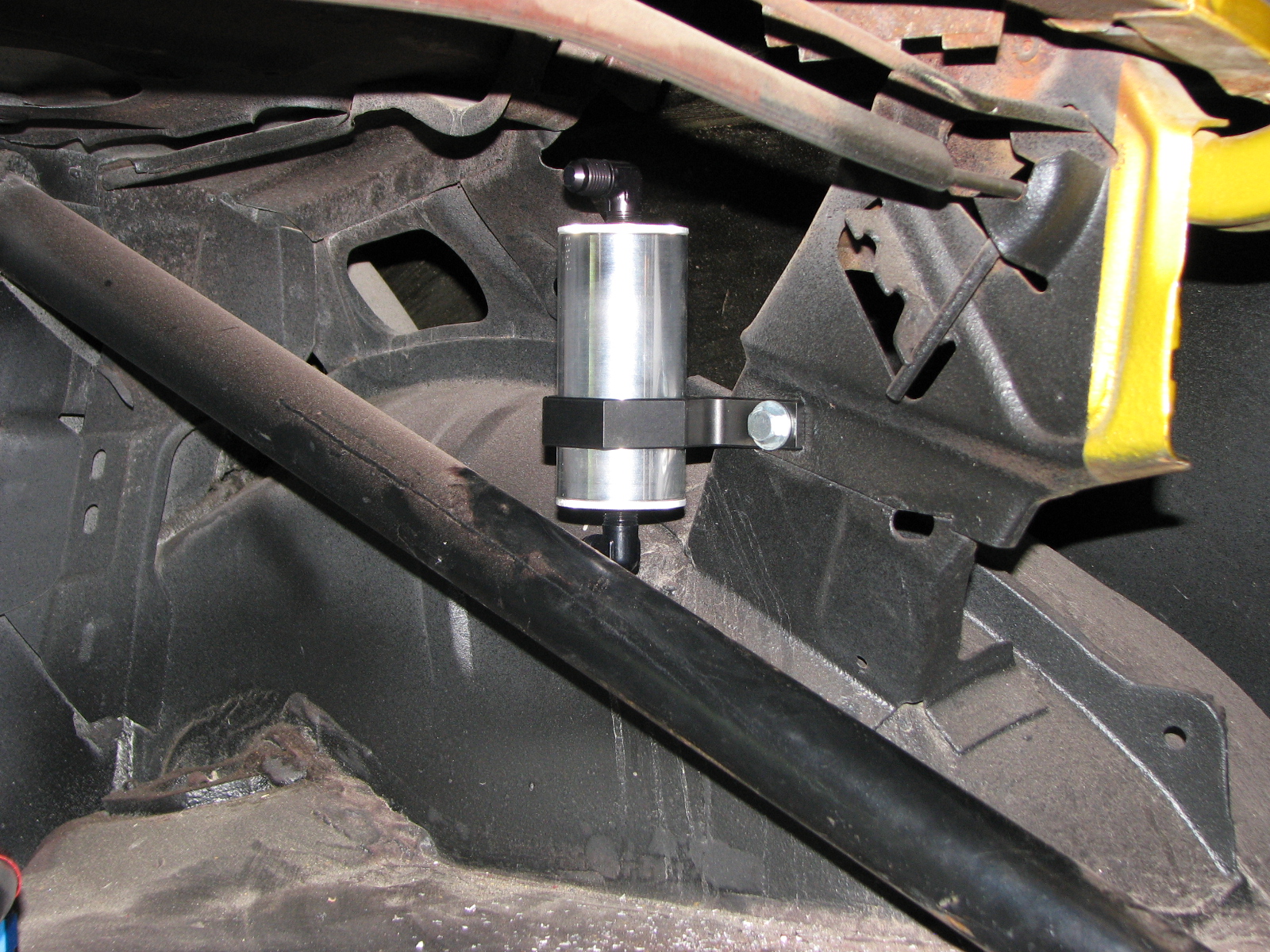

My lakes racing model a roadster pickup uses an aeromotive 62 gallon aluminum fuel tank with an internal 340 lph stealth fuel pump. As the name suggests an emergency vent allows pressure in the internal fuel tank to be released in the event of a build up. Close the manual vent after you have finished filling the tank. For a 10 x 1 7 tank wetted area 534 sq. Keep your boats fuel vent screen clean. Also the vent line cannot have a dip in it where fuel or condensation can get trapped in the line.

Open the manual vent valve if the tank does not have an automatic vent or a one way air check valve installed before you remove the cap to fill the tank. Without proper ventilation one can turn a rail car as seen in the video above into a pop can. If you are running a vent line it is important that the line is ran higher than the highest point on the tank including the fuel filler neck. Table lists wetted area and cfh for common sized vertical tanks. If there is a pump attached to the tank and that pump is drawing suction from said tank it is imperative to properly vent the tank. If fuel becomes trapped in the line your tank will then build pressure or vacuum until there is enough pressure to purge the vent which will cause gas andor odor to come from the vent line.