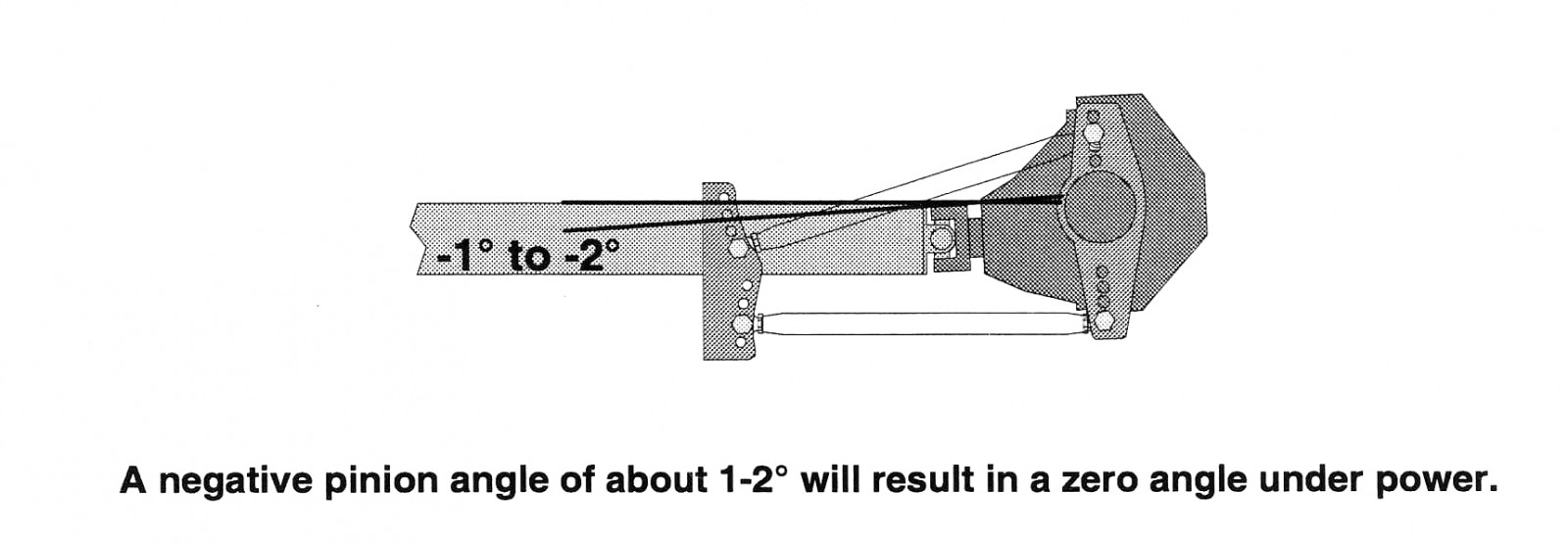

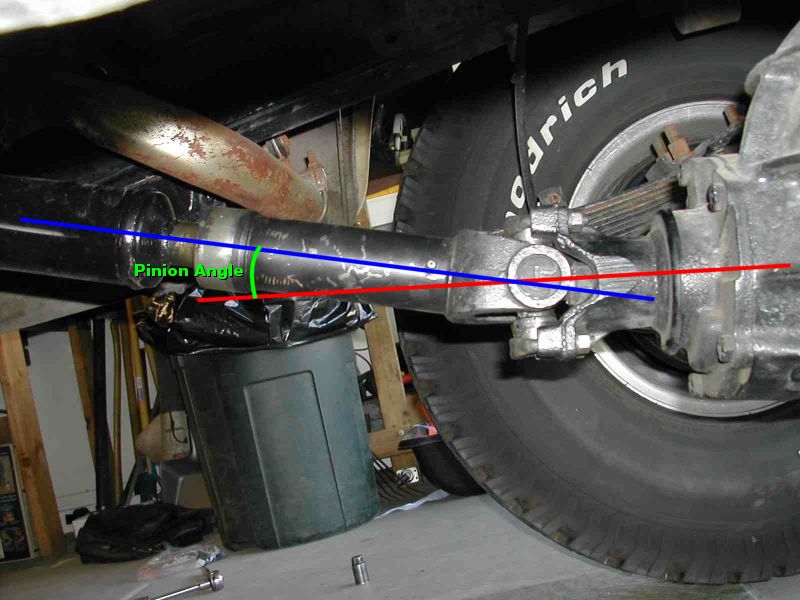

Rotate the pinion so that the ujoint caps on the yoke are pointing up and down. Pinion angle can be adjusted by adding tapered shims between the semi elliptic springs and the mounts on the axle housing.

2 Link Instruction And Pinion Angles

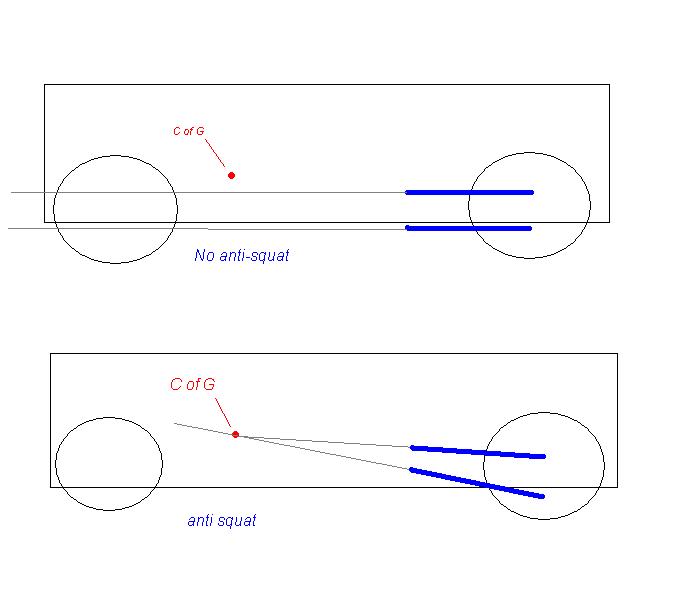

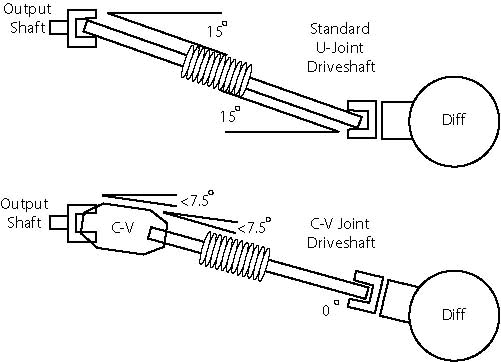

How to set the pinion angle. In this case you have to put a wedge on the back side of the saddles to tip the pinion angle down. The goal is to create a straight line from the back of the crankshaft through the transmission driveshaft and the pinion of the. Then remove the driveshaft from the yoke no need to totally remove it and spill tranny fluid everywhere and place the angle finder on the end of the yoke. If the vehicle is equipped with leaf springs then you can use wedge shaped aluminum shims to move the pinion up or down. Setting the pinion angle is the final step in driveline alignment. Pinion angle can be changed on radius rod style suspensions by adjusting their length causing the pinion to rotate up or down.

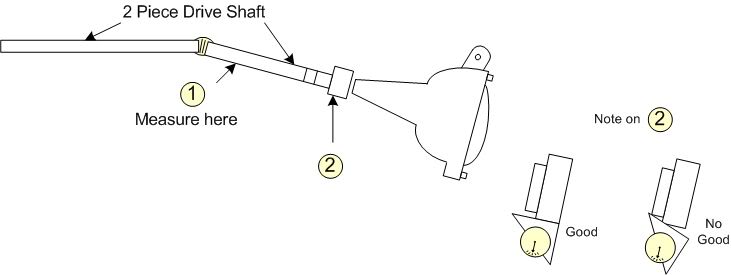

To find the working angles follow these steps. Place angle finder on bottom of driveshaft and write down the reading. The angle from vertical will be equal to the angle of the centerline of the pinion gear to the horizontal. Place an angle finder on the bearing cap and take note of the reading. Begin by measuring the angle of the driveshaft and writing it down. Find the difference between the two readings and this will be that u joints working angle.

A good example of having negative enginepinion angle is when you lower a 1 ton crew cab where you lower the front more than the rear and there is quite a rake. Set the angle finder on the face of the yoke where the u bolts go through. Rotate the driveshaft 90 and repeat step one. On a triangulated four link factory gm or ford the upper bars are also used to set the pinion angle by adjusting both uppers the same direction and same amount. Sometimes the face.