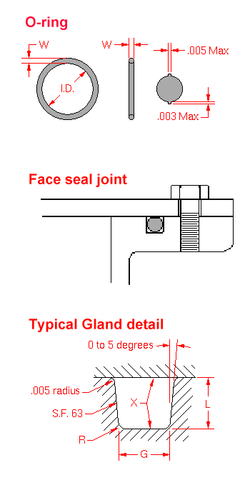

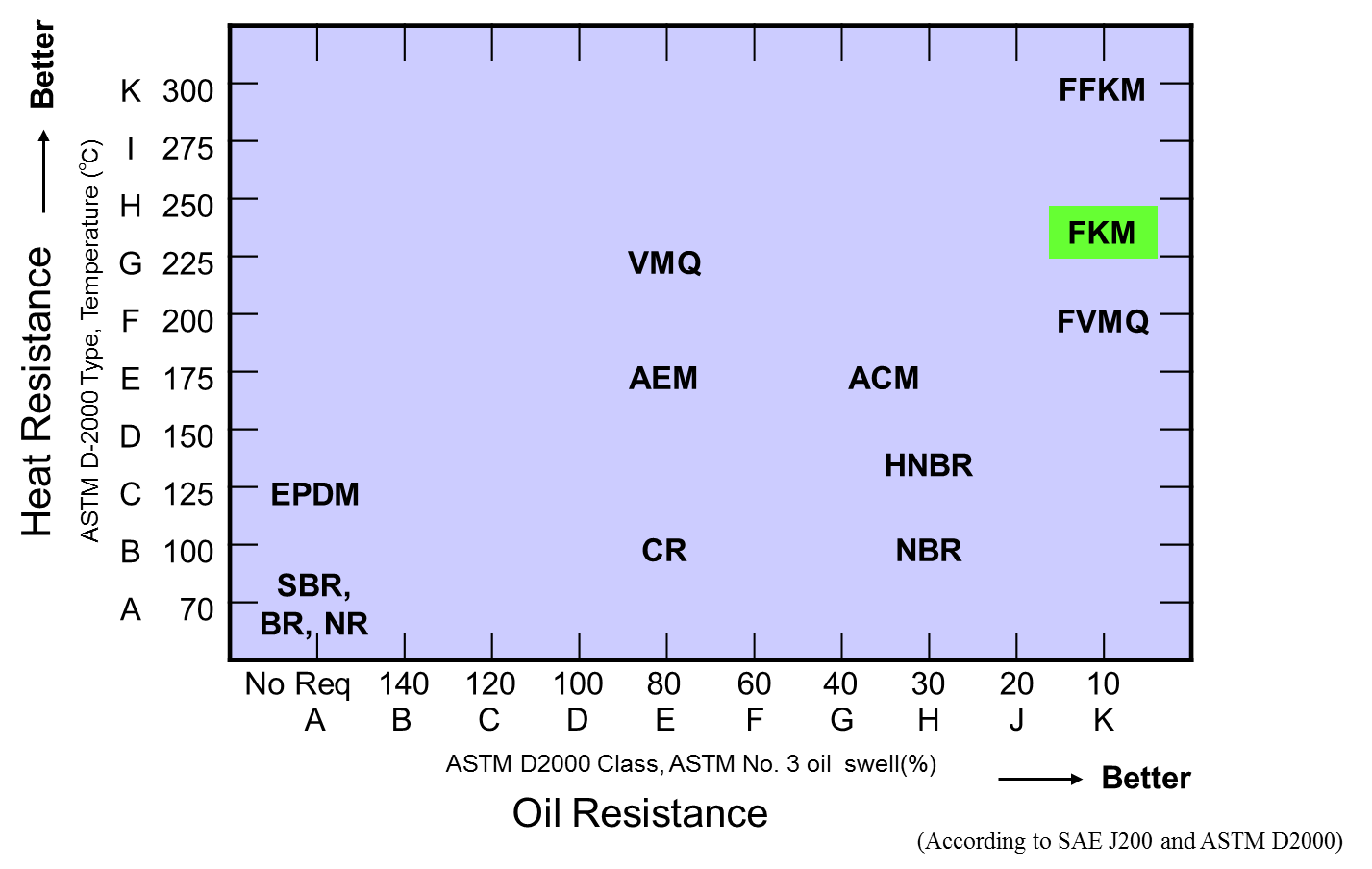

O ring are one of the most commonly used fluid power seals. Note that each type is actually a family of rubber compounds.

Fluoroelastomers Fluorochemicals Daikin Global

O ring material for transmission fluid. O ring materials compatible with automatic transmission fluid select a material to show its compatible chemicals aflas 4 buna n nitrile 4 butyl 1 chemraz 4 epichlorohydrin 0 ethylene propylene 1 fluorocarbon 4 fluorosilicone 0 hypalon 2 kalrez 0 natural rubber 1 neoprene 3 nitrile hydrogenated 4 polyacrylate 4. Aem is the most cost effective but this material degrades more quickly in transmission fluids. O ring groove design guides o ring groove dimension guidelines for standard o ring grooves metric o ring grooves jis o ring grooves and other o ring gland designs. A widely used economical material that has strong wear resistance and mechanical properties. The term buna n is really not much more specific than the term steel. Each of these material types has its pros and cons.

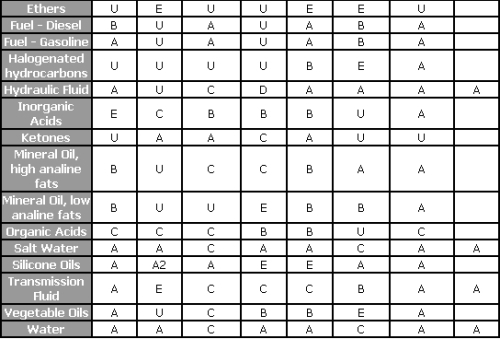

They can also be made from a number of different substances. Both these material types have their advantages and disadvantages. Heres a guide to the kinds of o ring materials we use how they are used and when to avoid using them. For the purposes of this article we will focus on just three common rubber types found in o rings and similar automotive seals. 55 to 250 degrees fahrenheit. O ring chemical compatibility chart learn how different o ring materials and chemicals interact.

One commonly used material for o rings in automatic transmissions is ethylene acrylic elastomer aem also known as vamac. These seals have a simple donut shaped ring technically called a toroid and are manufactured using pliable material such as elastomers like silicone buna n and ethylene propylene. In addition to this material various fluorocarbon fkm viton elastomers are also used in these applications. Fluid compatibility guide a detailed list of fluidschemicals with their compatibility ratings for use with the most common o ring materials. Ethylene acrylic elastomer aem is the most common elastomer in north america but various fluorocarbon fkm elastomers are also used. Basic o ring chemical resistance compatibility information is based on isolated generic o ring material testing in optimal conditions at room temperature and pressure.

Buna n viton and epdm.