Wrapped brazed steel is the norm for brake lines. It will be difficult with cheaper hand held tools.

Brake Line Splice Ricks Free Auto Repair Advice Ricks Free

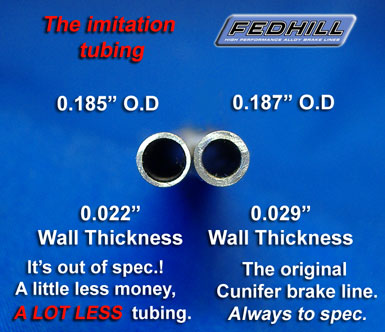

Stainless steel brake lines vs copper nickel. Stainless tubing is harder to bend and double flare. Normal steel brake line is coated in a corrosion resistant material. Answer to all your mini me timing questions belt cam ignition tdc teeth all of it. Cunifer copper nickel brake line is corrosion resistant on the inside. Plain copper tubing will not take the pressure of brake fluid. Depending on where you purchase it from nickel copper tubing can run higher or lower than stainless but always significantly more than cheap ol steel.

If this material fades or is scratched the plain steel line underneath is exposed and will rust. One major thing people dont realize about brake systems is that even dot 3 or 4 brake fluid will absorb ambient moisture and hold it in suspension. Original steel lines will give your mustang a classic factory original look while the more modern stainless steel lines will rust less than the original steel. However stainless will be more noble that the copper nickle and has a higher potential for reacting with aluminium so thats still and unknown but would be great for the caliper connection i imagine. The replacement brake line kit i got for my mustang is stainless steel. These come bare or coated in polymer wrap for corrosion protection.

Inside those steel brake lines there is no epoxy or zinc alloy coating to protect your lines. This will double flare and bubble iso or single flare very easily. But when you look at the job ahead of you and the potential lifespan of the tubing that higher cost can quickly start to look rather negligible.