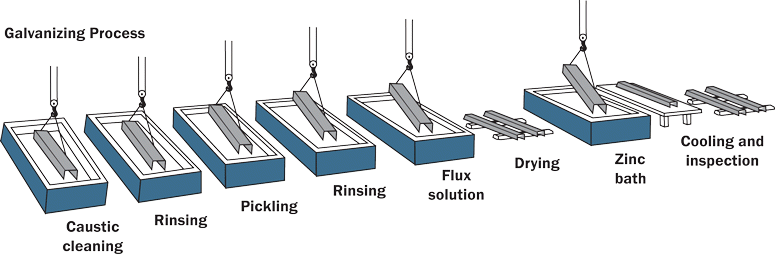

Cleaning of the substrate is done in order to remove any dirt rust oil etc from the surface. The flux is generally a solution of zinc ammonium chloride.

Zinc Plating An Important Part Of Today S Auto Manufacturing

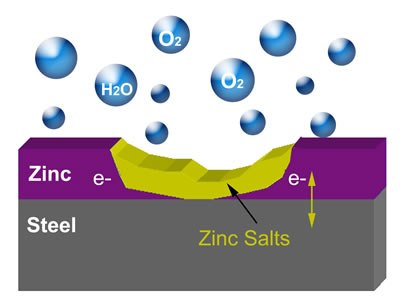

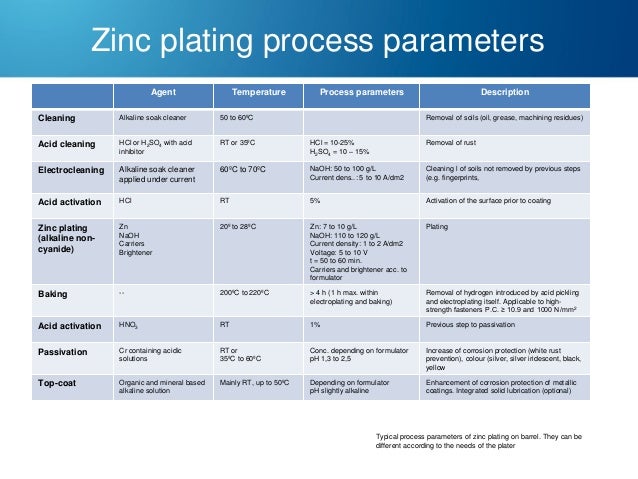

Zinc plating process steps. Therefore while performing the electroplating process steps appropriate current densities should be used. Activation or pickling of the metal involves removal of oxides and scales from the surface by using various acid. After plating hexavalent and trivalent chromate conversion coatings can provide up to 500 hours to white salt formation per astm b 117. On the commercial scale zinc electroplating is done by the following steps. Typical steps in electroplating process. Zinc plating methods one method for applying a zinc layer to a metal part is via hot dip galvanization.

Surface of the metal is cleaned in alkaline detergent type solutions and it is treated with. Any contamination on the surface of the. The first step is to clean the substrate the metal you wish to plate. To finish the preparation of the substrate it goes. Cleaning and pickling as described above for alkaline cyanide zinc processes activates and prepares steel parts for plating. Heres an overview of how a typical zinc plating process works.

With reverse current electroplating in which at regular intervals plating current is reversed for a second or so the polarization effect becomes negligible even with the very high overall speed of plating. Steps of commercial zinc electroplating. Step 1 cleaning the substrate. Proper cleaning and. The surface must be free of contaminants for bonding to take place. Step 2 activation of the substrate.

Preparing the plating solution zinc plating requires the immersion of the substrate into a specially formulated. The part is then dipped into a vat of molten zinc that has a layer of flux floating on top of the zinc. After plating chromate conver sion coatings that can provide up to 1000 hrs to white salt formation per astm b 117 are available and may provide a cost effective alternative to alloy plating. Acid in order to remove any rust or surface scales. Preparing and cleaning the surface its essential to thoroughly clean the surface of the substrate prior to plating. A step by step guide to the zinc electroplating process.

Zinc electroplating steps step 1. The process shown below takes about 90 minutes to complete. Cleaning and pickling as described above for alkaline cyanide zinc processes activates and prepares steel parts for plating. This is the process for plating steel aerospace parts with cadmium.