A cylinder leak down test requires the removal of all the spark plugs. It deals with how well the cylinder is sealing and nothing else.

How Much Longer Will Your Diesel Engine Last Diesel Power

Diesel cylinder leak down tester. The universal rule for cylinder leakage is no more than 30. You calibrate the gauge to 0 by turning the regulator then you hook it up to the cylinder. Leak down test kit not a compression tester the performance tool w89729 leak down test kit can quickly diagnose internal engine problems such as bad rings valves and leaking head gaskets. The abn cylinder leak detector appx. A threaded coupling is screwed into a spark plug hole. So the great thing about the cylinder leak down test is that.

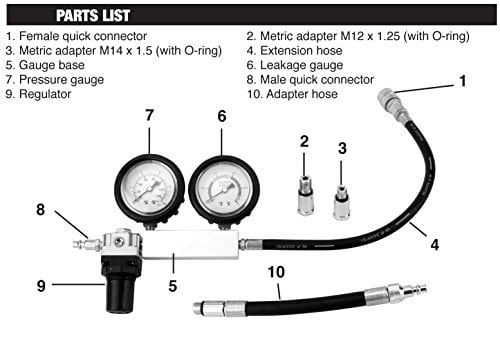

It is also important to note this type of tester is not rated to measure more than 100 psi. An engine leakdown test is a compression test in reverse. A cylinder leak down test takes more time to perform. Pressurized air is supplied to each cylinder and in moments displays a rate of leakage measure from 0 to 100. 31 comes with 12mm and 14mm fittings and must be calibrated before each use by manipulating the schrader valve for the regulator. The dual 2 12 gauges read 0 100 psi and 0 700 kpa and feature chrome bezels and rugged protective outer boots.

The cylinder leak down test reading is expressed in a percentage. Product description otcs 5609 cylinder leakage tester kit quickly diagnoses internal engine problems like bad rings valves and leaking head gaskets and comes complete with adapters for most applications. The best gauge to use is a dual gauge leakage tester. Consequently good cylinder leakdown readings should be below 5 8. This cylinder leak down tester gauges leak down tests more accurately than standard compression tests. But can give you a more accurate and detailed picture of the engines overall health.

Instead of measuring the engines ability to create pressure compressed air is introduced into the cylinder through the spark plug hole. It will have two gauges one with air pressure and one with leakage and an adj. Furthermore the readings are not affected cam timing or even engine cranking speed. Compressed air 80 to 90 psi is then fed into the cylinder.