Then the load is placed in the compression tester between the compression platen and the base. Put the compression test adapter into the engines first cylinder.

Ohc Compression Tester 5 Piece Kit

How to use a compression tester. Most compression testers come in two or more pieces that should be threaded or snapped together from the parts closest to the engine out all only by hand. Step 1 remove the fuel pump and fuel injection fuses. As the tested cylinder comes up on its compression stroke. The leakdown tester is less common and you need to get a. With the use of a few hand tools a compression tester and about 20 30 minutes you can perform the test at your very own home. Regarding how to use a compression tester there are several steps involved.

The other four are to replace various size spark plugs. Preparing the testing unit. Hold the throttle all the way open. Hook up compression tester to a cylinder. Look down on the engine to figure out which. With a compression tester a few hand tools and 20 minutes you can try this yourself.

Use a dab of grease or vaseline to lube the threads and o ring on adapter. First of all connect the tester to a cylinder and turn the engine over 6 to 8 compression strokes. You will be able to hear the cranking speed slow. This should include a representative sample of the products whether they are boxes pallets. Disconnect the main wire to the coil and spark plug. Use the correct size adapter to screw into the spark plug hole.

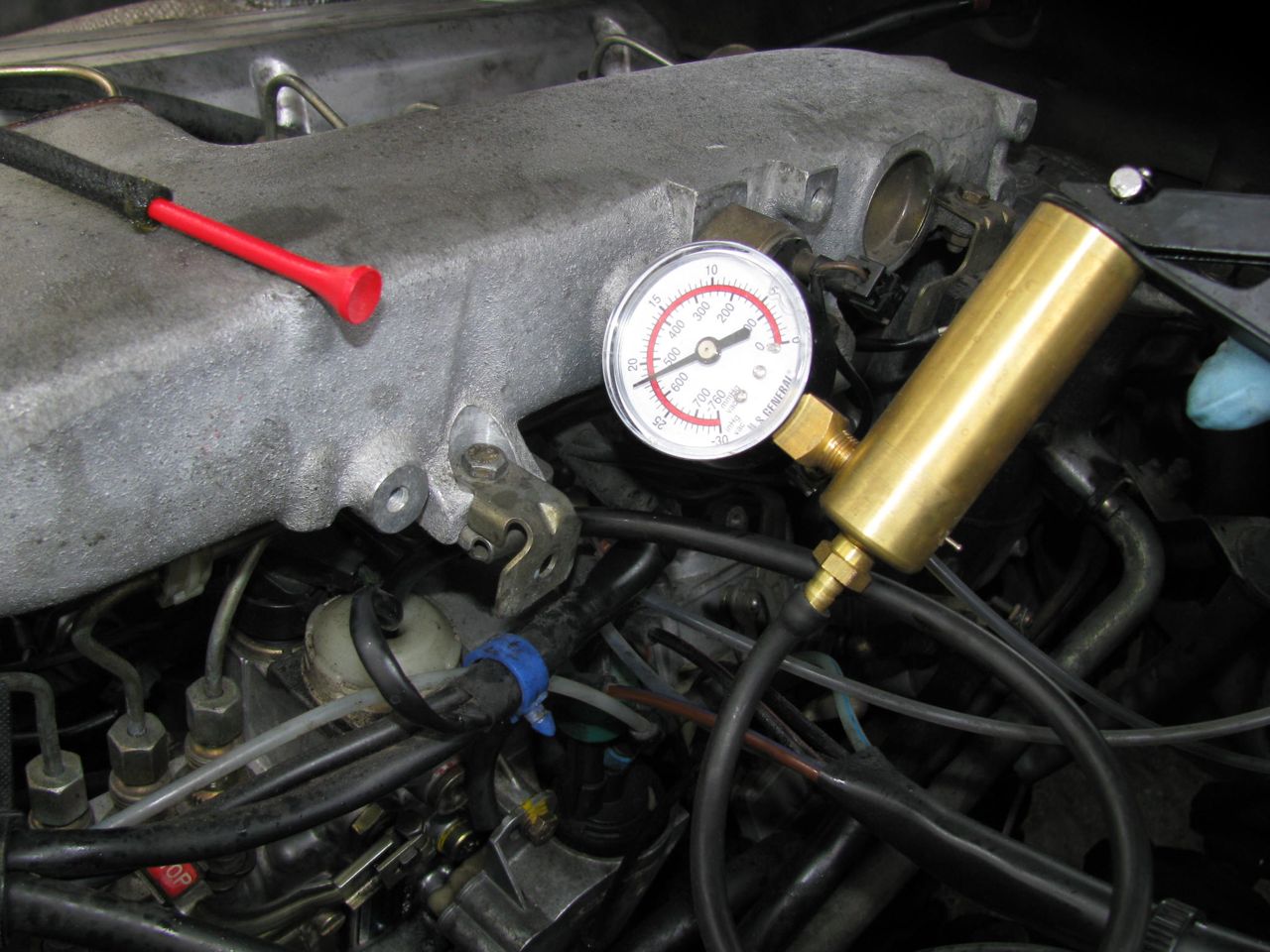

Two of them with the tubes in the picture above are to hold directly against the cylinder hole where the spark plug was. The compression tester is the more common of the two and you can usually rent one at your local auto parts stores loan a tool program. There are several adapters in a compression test kit. This will prolong o ring life. Performing the test 1. Next have a friend crank the engine for five seconds or so while you observe the gauge.

Connect the compression gauge to the opposite end of the hose. To pick up any of the products used in this video check the. Note how fast the compression increases and write down the highest reading. Crank the engine at least 4 times to. If youre testing a diesel engine make sure youre.