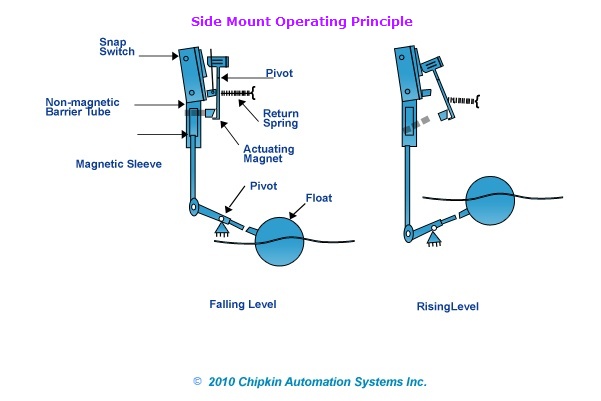

The sensor probes actually act as their own sensors and do not pass electricity through the probes which keeps them from fouling degrading and deteriorating. One pattern uses a reed switch mounted in a tube.

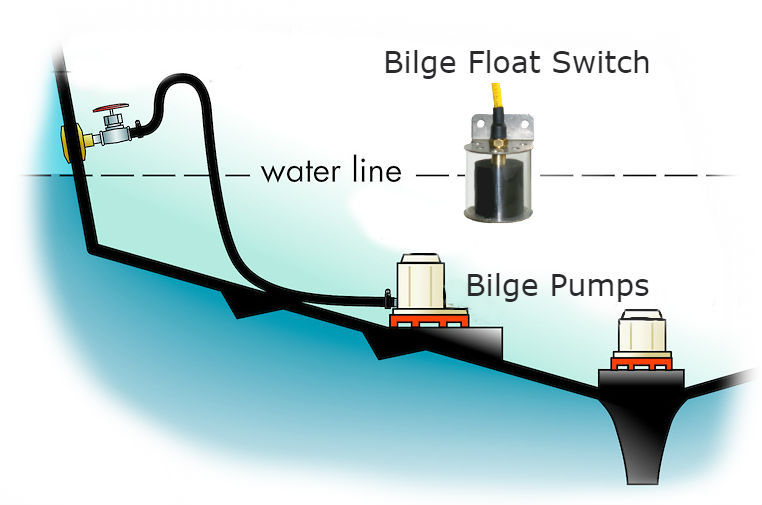

Bracket Mounted Bilge Float Switch Liquidlevel Com

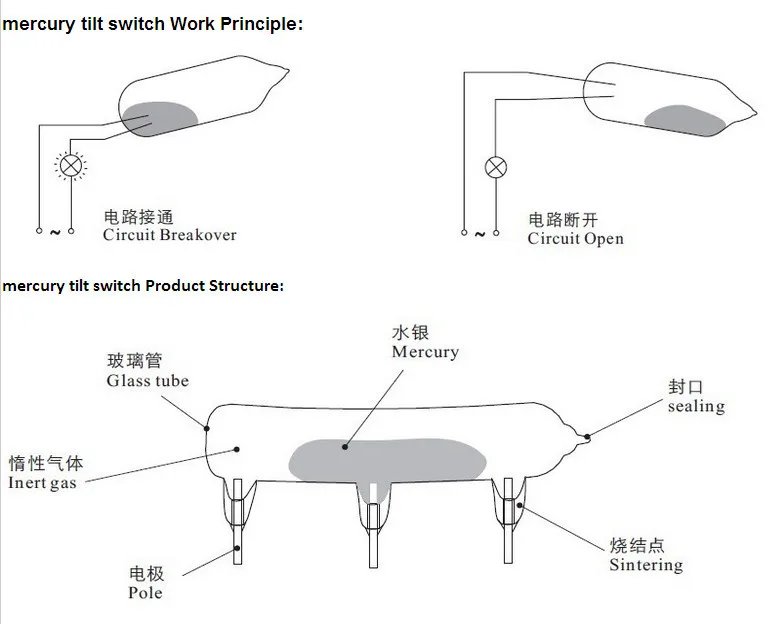

How does a mercury float switch work. This design is used in relays in industrial applications that need to switch high current loads frequently. Description the eco float is a mercury free float switch for controlling liquid levels in a variety of applications. How new float switches work water level controls float switches work by using probes instead of float switches. There is a minimum differential between on and off of approximately 35 inches. In a float switch the magnetic reed switch is hermetically sealed in a stem most often made from plastic or stainless steel. The float encases a sealed magnet which moves up and down the length of the stem as a fluid level rises and falls.

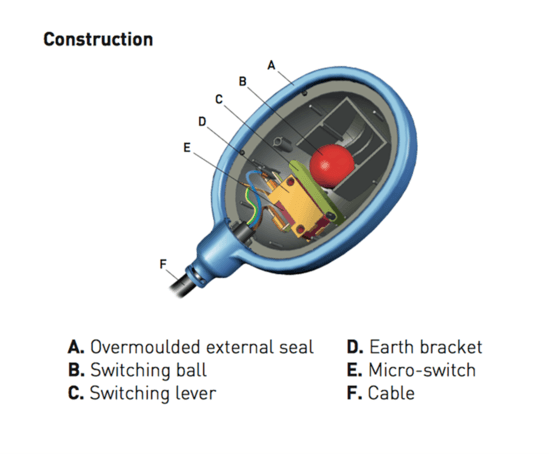

New float switch working principle float switches and water level controls usually start out closed meaning there are no alarms that need to be triggered because the water level is at the predetermined height. A snap action switch is activated by a steel ball rolling back and forth within a switching tube in a plastic float housing. The mercury displacement switch uses a plunger that dips into a pool of mercury raising the level in the container to contact at least one electrode. When the float raises the magnet to the reed switch it closes. One type of float switch uses a mercury switch inside a hinged float. A float containing a magnet surrounds the tube and is guided by it.

Once the cooling tower starts using the water for its industrial processes the water level starts dropping. Another common type is a float that raises a rod to actuate a microswitch.